Heavy-Duty Engines 2026

24-11-2026 – 25-11-2026 – Salzburg, Austria

Cooperation partners

Identify and utilize synergies effectively

Commercial Vehicles | Agricultural and Construction Machinery | Marine

18-11-2025 – 19-11-2025 – Colmar, France

Commercial Vehicles and Mobile Machinery

Sustainable powertrains, application-specific solutions, components

Large Engines

Gensets, dual and multi-fuel engines, marine propulsion systems

Environmental Impact

CO2 reduction, exhaust gas aftertreatment, alternative fuels

Dr. Volker Groß

Liebherr-Components Colmar SAS, France

Ismo Hämäläinen

AGCO Power Inc., Finland

Christof Klitz

FIPRA International SRL, Belgium

Tim J. Proctor

Cummins Inc., UK

Moritz Köllner

BMW Group, Germany

Prof. Dr. Peter Pickel

University of Bonn, Germany

Tour of the Liebherr-Components Colmar SAS and Liebherr-Mining Equipment Colmar SAS plants

Author: Marc Ziegler

Report from the 20th International Heavy-Duty Engines 2025

MTZ Conference Heavy-Duty Engines 2025: How can large engines for agricultural and construction machinery, marine applications, and gensets achieve environmental targets?

Prof. Dr. Michael Günthner, the new scientific director of the event, welcomed guests to the Colmar Exhibition Center. Günthner emphasized the great importance of heavy-duty engines and mobile machinery, which he said also includes agricultural machinery. The program for this year's event was structured with this in mind. The aim is to identify synergies and make targeted use of them to achieve environmental goals.

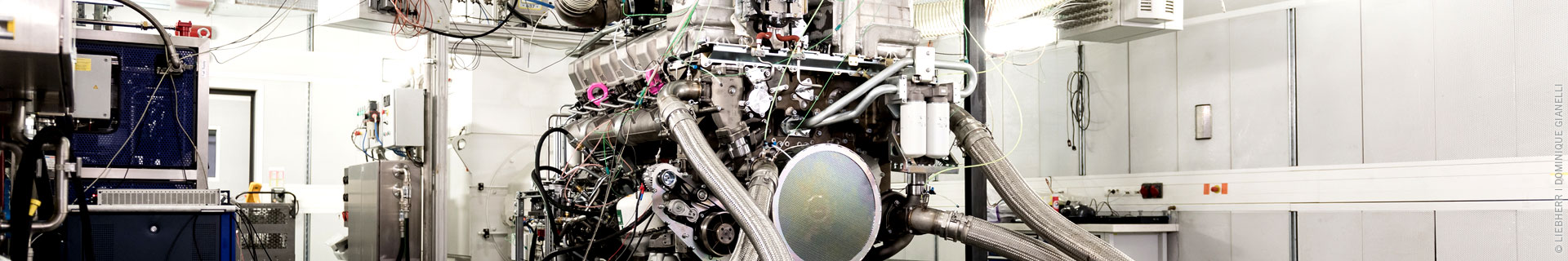

The keynote session was opened by Dr. Volker Groß from Liebherr-Components Colmar. He highlighted the enormous challenges in terms of total CO2 emissions in the areas of mining and construction machinery. In the mining sector, emission targets are driven not only by legal requirements but also by the protection of employees. In the construction machinery sector, many municipalities now demand the lowest possible emissions in urban areas, right down to locally emission-free construction sites. Liebherr covers the entire portfolio of possible drives for a wide range of operating conditions. These include combustion engines, transmissions, and hydraulics, as well as electric drives and the associated power electronics.

In the mining sector, dual-fuel engines are being developed specifically for the use of sustainable ammonia as an alternative fuel. Groß went on to show that this could achieve a CO2 reduction of 88 % (87 % CO2e incl. N2O). Hydrogen and methanol are other possible alternatives, with the latter recently coming back into focus due to the relatively quick feasibility of an engine concept. On the other hand, electrically powered vehicles are also in use. Since the batteries would have to be very large for all-day use, open-pit mining machines are often powered by cable electricity. From 2026, 16 machines with a standardized battery will be feasible, albeit with a low C-rate of 2. The largest battery-electric machine currently available is a dump truck with a payload of 244 tons, equipped with a 32 MWh battery that can be charged at 3 MW in one hour. Support and dynamic charging via overhead lines during operation, for example when driving uphill, are also feasible and can reduce costs while increasing productivity by up to 40 %.

The second keynote speech was given by Ismo Hämäläinen from Agco Power, who presented the future of the combustion engine in the off-highway sector. Agco produces powertrains for a wide range of agricultural and forestry machinery. CO2 emissions in Europe are to be reduced to around 108 Mt CO2e/a, while food production is to be increased by 50–60 % by 2050. On the road to net-zero emissions, Agco is therefore relying on all available drive technologies, from conventional combustion engines with fossil and sustainable fuels, hybrid and fully electric drives, to hydrogen and methanol fuel cells. The drive technologies are primarily based on performance requirements. However, it seems clear that high-performance applications will continue to rely on combustion engines in the future, which is why climate-neutral fuels are so important.

Packaging is the biggest problem for battery-electric applications. Even with a 100 kWh battery, the recently unveiled Fendt tractor can only be used for short distances. Hämäläinen sees the greatest potential for development here. When investigating various alternative fuels, it is important to consider not only the different volumes for comparable energy contents, but also, of course, the fuel price. In both cases, diesel is still by far the cheapest. However, Hämäläinen sees opportunities in local production, for example of bioethanol directly on the farm, to reduce these costs. In any case, the technologies are available. What is missing is the legal framework, for example to offset the increased costs of sustainable fuels.

In the third keynote speech of the opening session, Christof Klitz from Fipra International explained the current developments in CO2 regulations at EU level. The lawyer explained the status of current discussions surrounding CO2 reduction targets and the ban on combustion engines after 2035. The geopolitical situation is extremely tense due to the current war in Ukraine, but supply chains, customs regulations, and protectionism are also putting strain on the political system. According to Klitz, the European Commission is currently attempting to mitigate the consequences of the hasty green transformation and at the same time strengthen the automotive sector again, for example by trying to bring production back to Europe, building up battery production capacities, and consolidating and amending a whole series of laws in the automotive sector.

The joint "European electric car" is one example of how to shift value creation from Asia back to Europe. Klitz emphasizes that the legislative process in Europe usually takes two to three years due to the many different parties involved. The ban on combustion engines is currently being reassessed, a process that has been brought forward by one year. Although there is much discussion here, very little is happening in the process, partly because people are waiting for signals at EU level, for example from Germany or France. Nevertheless, a draft law is expected to be ready by the end of the year. Many initiatives are currently failing because they do not represent a business case for manufacturers. Decisions are therefore awaited in all areas of the mobility sector. Klitz urgently recommends continuing to seek discussion with political decision-makers, drawing on expertise and technical knowledge.